Brick Cladding Mechanical Systems

Brick Cladding Panels

We are now able to offer this exciting new Brick Cladding product that is causing lots of interest in the construction industry. What's so exciting about it? To be honest, it's not so much a new product as a re-engineered version of an old product. The changes however, reflect a much needed alternative to traditional brick backed cladding.

You see, in traditional products, the brick faces are physically attached to a backing plate or board. This is usually done by using an incredibly strong adhesive or by bolting the bricks to a rail or board. However, there are a number of downsides to the traditional product such as bricks becoming unstuck, cracking under movement and pressure. Not to mention the sheer weight of these boards and the support needed to install them.

Bricks can be made from recycled materials in a range of finishes that offer great thermal properties too! An altogether greener product.

The new mechanical brick cladding system is different in that installers fit a lightweight rail system into which the brick faces slide. It's a little like tongue and groove style boards that we're used to with flooring and wood panelling.

The benefit of this new system is:

- It is a much lighter system to handle

- One person can pretty much install it single-handed

- Once the rails are in place, inserting bricks is simple

- Less supporting tools are needed to install

- Much safer for the fitter

- Lighter and safer for building construction

So imagine not needing pallet loads of bricks. Think about how much less mortar and mess there would be. All that manpower you could save by having us fitting masonry support and brick cladding in one go!

Yet another innovation of this product is the fact that the brick faces can be made from a whole range of materials such as brick, concrete and the lightweight Glass Reinforced Concrete.

"Brick walls just got a whole lot lighter, a whole lot safer and a lot more cost effective."

Supply & Installation

Our installers are trained specifically to fit most Brick Faced cladding product on the market. In many cases we can also supply Brick Cladding products or simply install. We also fit nationwide so no matter where you are, no matter what your need, we've pretty much got it covered.

Comparing Traditional Products and Brick Cladding Products

| Traditional Brick Slab or Screw-in product | Brick Cladding |

|---|---|

| Usually very heavy slabs of bricks bonded to a concrete plate | Lightweight, prefabricated aluminum rails and bricks |

| Requires multiple people to install and secure | Can be installed by a single installer |

| Is slow and heavy, laborious work | The lightweight nature makes installation quicker and more streamlined |

| Can be hazardous to person safety | Safer to handle generally due to the lightweight construction |

| Bricks are know to fall away from the bonding over time | The brick faces are held in place mechanically so there is no fall away |

| Requires specialist bricklayers to create and install | No need for specialist bricklayers, just a trained installer |

| Slow to install, meaning greater costs | Trained worker focused on installation only can complete the job much quicker saving time and money |

Typical Lead Times for Brick Faced Products

| Bolt Ups | Costing / Quotation | Site Delivered From Approval |

|---|---|---|

| Basic System | Two Working Days | Three to Four Weeks |

| Complex System* | Five Working Days | Six to Eight Weeks |

| Mechanical Cladding System | Costing / Quotation | Site Delivered From Approval |

|---|---|---|

| Basic System | Two Working Days | Three to Four Weeks |

| Complex System* | Five Working Days | Six to Eight Weeks |

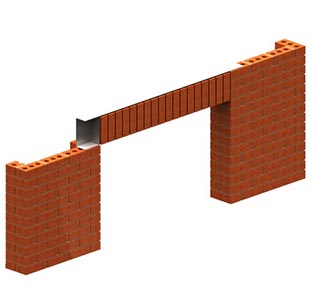

Brick Clad Soffits

We also install Brick Clad Soffits?

In conjuction with fitting brick clad panels, we can also supply and fit a range of brick clad soffits and lintels.

"This market leading Soffit solution is around 70% lighter than traditional methods and can reduce fitting times by up to 90%."

Manufactured off-site and supplied as a prefabricated unit, these lintels require no work other than installation of the lintel itself. With our specialist fitters, the lintels can be installed faster without the need to use a bricklayer, saving you time and money.

Brick Clad SoffitsVision Installers

Vision installers are trained and experienced in the fitting of masonry support systems, we offer time served operatives that are able to overcome any masonry or brickwork fitting issues. As with any tradesman the longer you do something the quicker and better you get at it. Our teams will fit up to 60 metres of masonry angle per day depending on the specified fixing. This not only allows bricklayers to be more productive but also speeds up tight site programmes which is essential in modern day construction.

With Vision fitting you are guaranteed that it is fitted to specification with the correct fixings and fixing centres. All fixing bolts are tightened to the specified torque settings. We will also ensure that your brickwork system is fitted with the correct shims where necessary. By using Vision, more metreage will be fitted on a daily basis. A QA sign off sheet for each elevation fitted will be provided daily which gives you a holding point with clerk of the works. Your support system will be fitted once fitted right.

What Our Customers Say

Richard and the team at Vision are always able to help. Last minute requests or on-going work, Vision are a reliable company that we do not hesitate to use.

They provide competent labour and an efficient billing & work evidence system that allows us to know where we are at all times.